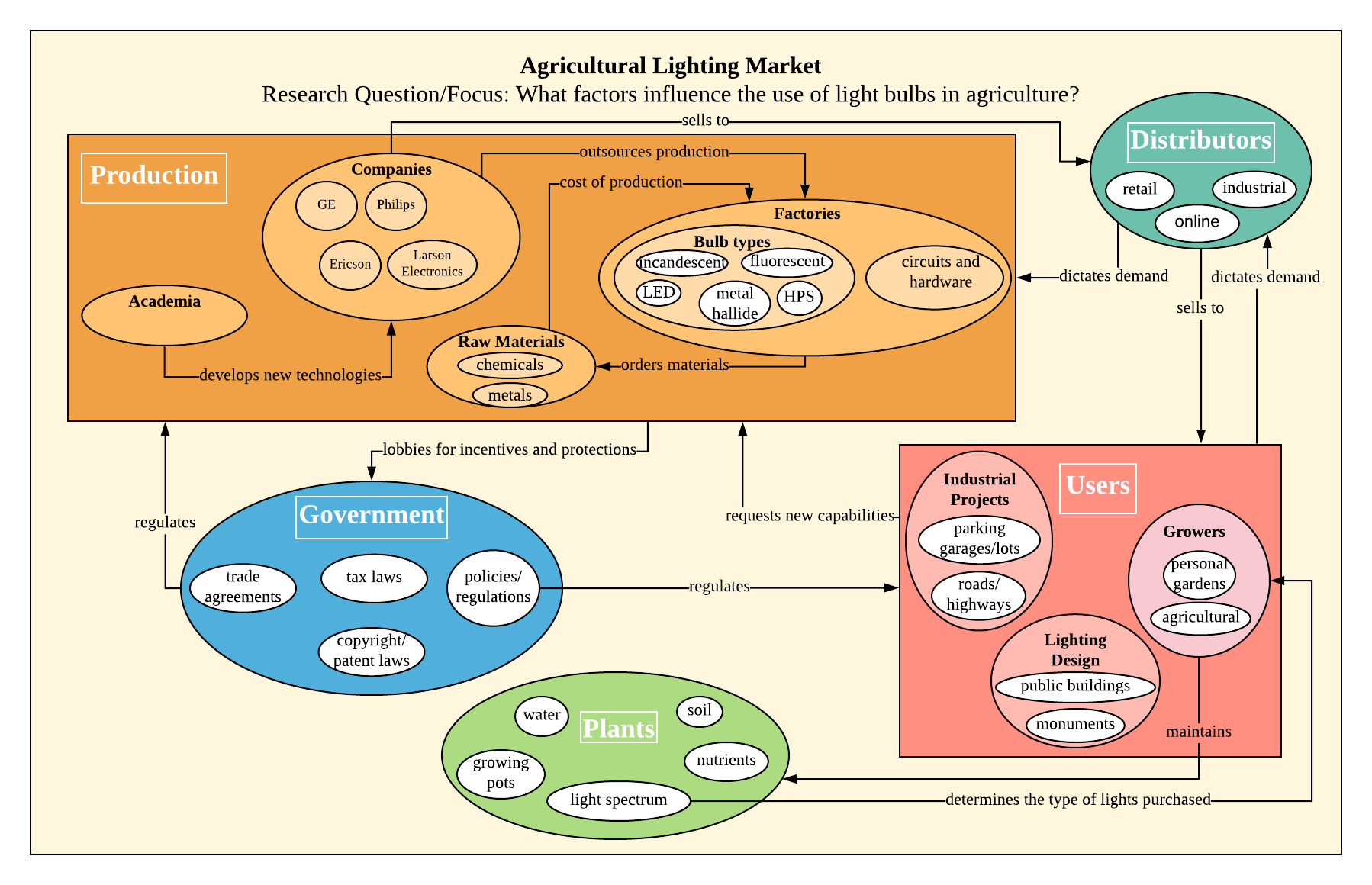

When plant growers are looking for artificial lighting solutions for their gardens- either because they live in a cold climate that requires a greenhouse, or because they are building an indoor home garden- they have a variety of lighting options from which to choose. However, not all lights may be appropriate for plants. Furthermore, bulbs used in agriculture are also often used in infrastructure, industrial, and consumer lighting projects which may value different aspects of the bulb higher than others, that may impact the bulb’s technological development. To better understand agricultural lighting systems, it is useful to first consider the impact of five main groups on the use of lights in agriculture:

Government

The government impacts the agricultural lighting system through the economic landscape, establishing trade agreements, tax laws, and other laws designed to encourage innovation such as copyright and patent laws. Additionally, the passing of safety, environmental, and labor laws impacts Producers as well as Users.

Distributors

The companies that make light bulbs do not sell them directly to end markets. Instead, distribution is handled by industrial wholesalers, online retailers, and consumer retail stores like Lowes and Home Depot. Distributors make decisions on which bulbs and electrical circuitry to stock based on demand.

Producers

The Producers of lights are comprised of: companies who develop the proprietary technologies (such as GE and their Lucalox glass), universities where technologies are further researched and refined, and the factories that build the technologies. Producers are driven by technical developments, labor and raw material costs, and customer demands. The government also plays a role in production, from negotiating trade agreements that impact the prices of raw materials and determining where companies can build factories to placing safety and environmental regulations on products. All these factors impact the development of light bulbs and other necessary electrical equipment.

Users

Almost all people make up the lighting industry’s customers, but it is useful to categorize them based on the varying needs of their lighting projects. Such customers are: individual homeowners, government infrastructure projects, corporate real estate developers, and agricultural growers. Individual growers compromise one subset of agricultural growers, while other growers include large scale agriculture and industrial garden projects, such as roof gardens or vertical farming. Like producers of bulbs, government regulations also impact Users. Building codes, safety features, energy efficiency requirements, and legality of plant material all impact which light bulbs are more appealing to Users.

Plants

The plants themselves also have requirements that shape user decisions. Plants require large quantities of light from a specific light spectrum for ideal photosynthesis. This means that lights with short lives, low lumen output, or light emission that falls outside of the needed light spectrum will not be appropriate for some plants and their growers. For example, fluorescent bulbs are long-lasting, but they produce a blue light spectrum which isn’t sufficient for plant growth because they need a balance of red light (Day n.d.). Additionally, too much heat will adversely affect the plants, so additional equipment may be needed if a bulb produces too much heat.

Outside of this network are wider dependencies which shape the entire market: the environment, money, and electricity. The environment, including seasons, weather patterns, and other factors impact the health of plants, agricultural production practices, and the conditions under which outdoor bulbs need to operate. Even producers and distributors may have to grapple with different conditions when producing and transporting their products. Money and the amount of capital available for investment, development, design, and maintenance impacts decisions at every level of the system. Finally, electric infrastructure is foundational to this technology.

This system has fostered a change in the demand for the high intensity discharge (HID) high pressure sodium (HPS) bulb over the years. The HPS bulb was initially designed at GE as part of their Research and Development (R&D) team’s investigation into new techniques in material science. During this time, they discovered ceramic glass strong enough to withstand the high internal heat created by the chemical reaction of sodium bulbs. This Translucent Aluminum Oxide, or Lucalox, was brought to the market in the 1960s and was used for commercial, industrial, and personal uses (“Inventing Six Modern Street Lamps”). Simultaneous to its discovery, scientists were developing other technologies for the creation of light, such as the electric ballast which could create the voltage needed for vapor lamps. When the sodium vapor lamp, Lucalox ceramic, and the ballast were all combined, GE was able to invent and market the high pressure sodium bulb. At the time, the HPS bulb was more energy efficient than its competitors and was able to generate a vast quantity of lumens (80,000-95,000 lumens), making it ideal for industrial purposes such as street lamps (“GrowBright 600 Watt HPS Bulb.” 2016). HPS bulbs can also be used for long periods of time (24,000 hour lifespan), remain highly efficient (about 40% efficiency overall) and are low maintenance (Stouch 2017).

Over the years, however, government regulations and tax incentives encouraged the production of more energy efficient and environmentally friendly lighting technologies. Onto the market came competitors such as the fluorescent and the LED bulbs, which produce less heat than HPS and were able to match or beat the HPS in lumen output. Industrial customers soon began to favor these more efficient technologies.

However, as some customers adopted these new options, the HPS bulb remained favored by the indoor horticultural community because the light spectrum of the HPS bulb, which includes both blue and red light, is ideal for plant growth. Producers have recognized this need in the agricultural community, and have designed LEDs and fluorescent bulbs which contain a wider spectrum of light. HPS bulbs are best for a plant’s flowering stages and should ideally be combined with metal halide bulbs, which are best for a plant’s growth stages. In contrast, newly developed LED bulbs can be used for the whole growth process and require no extra materials, such as the HPS bulb’s necessary exhaust vents. Similarly, due to the design of the LED bulbs, they are less fragile than HPS bulbs and are therefore harder to break. Further impacting grower decisions are the costs of various lighting systems. HPS systems typically have a lower initial start up cost, but they require more electricity to function (“LED vs HPS – Which Grow Lights Are Better?” 2016).

Despite these advantages, the efficiency and production of LED bulbs has not been fully tested, as they are newer products in the agricultural lighting market (Haze 2018). HPS bulbs remain respected as the best bulb to use for high-yielding growth, particularly for cannabis plants (ibid.). HPS dominance remains locked in, mostly due to the bulb’s standardization and popularity with manufacturing companies, its historical track record of success, and its reliably high lumen output (“HPS Servicing Guide” 2004: 10).